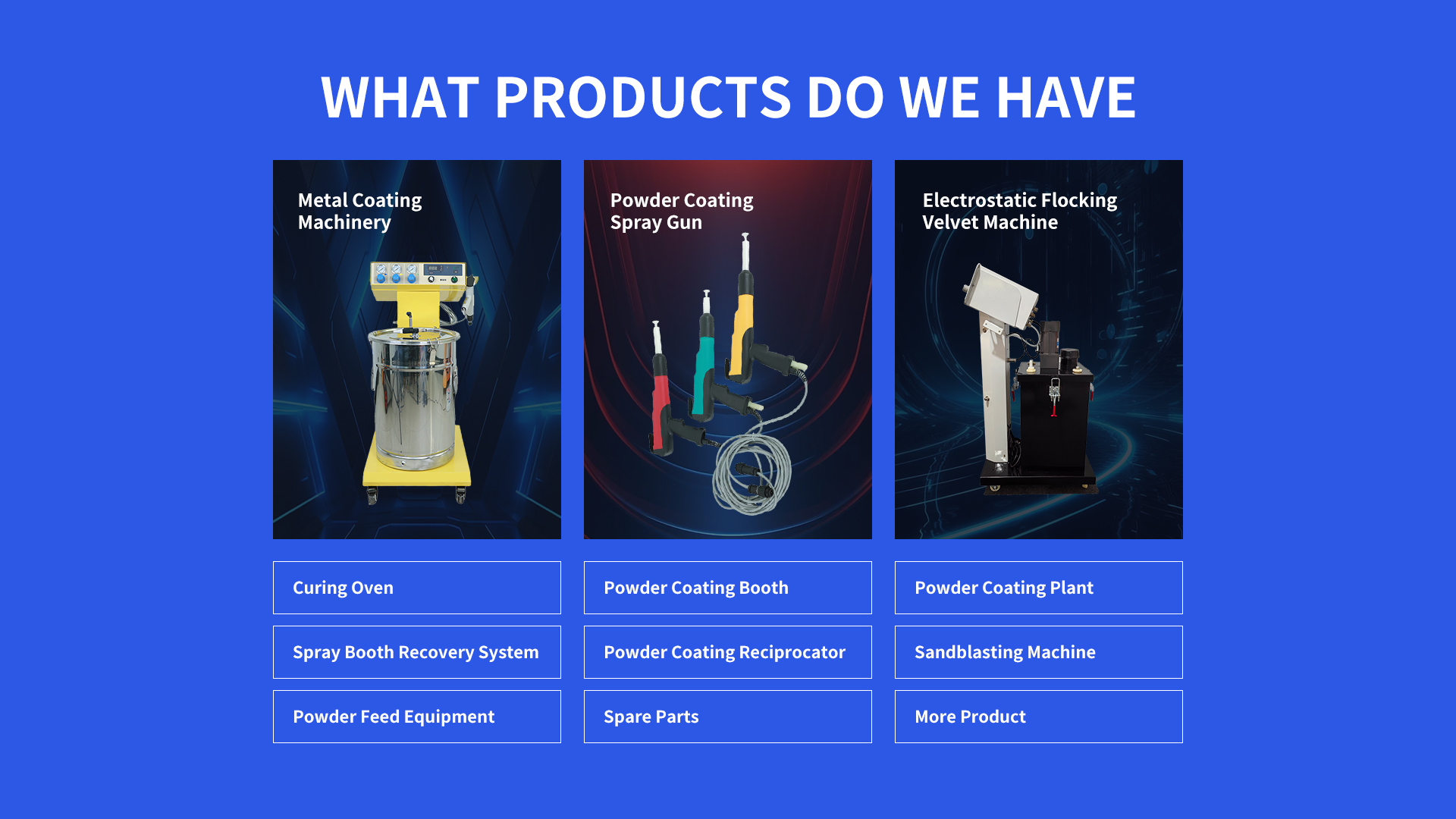

1. Manual Powder Coating Spraying Equipment Overview and Components

Manual Powder Coating Spraying Equipment is a user-friendly system designed for small-scale or customized coating tasks. Key components include a handheld electrostatic spray gun, powder hopper, grounding cable, air compressor, and curing oven (or heat lamp). The spray gun uses electrostatic charge to adhere powder particles to surfaces, ensuring even coverage. Compact and portable, these systems are ideal for workshops with limited space or budget.

2. Applications of Manual Powder Coating Spraying Equipment

This equipment is widely used in automotive repair, metal fabrication, furniture restoration, and DIY projects. It coats items like bicycle frames, tools, garden furniture, and machinery parts. Suitable for materials such as steel, aluminum, and heat-resistant plastics, it provides durable, rust-proof finishes for both indoor and outdoor use.

3. Pricing of Manual Powder Coating Spraying Equipment

Prices range from 300forbasickitsto5,000+ for advanced setups with high-efficiency guns and curing ovens. Entry-level kits suit hobbyists, while professional-grade models with adjustable voltage (20–80 kV) and larger powder capacities cater to small businesses. Brand reputation and warranty terms also impact costs.

4. Proper Usage of Manual Powder Coating Spraying Equipment

Surface Preparation: Clean and sand surfaces to remove rust or grease.

Grounding: Attach the grounding clamp to the workpiece for electrostatic adhesion.

Spray Technique: Hold the gun 6–10 inches away and apply in steady, overlapping motions.

Curing: Bake coated items at 300–400°F for 10–15 minutes to harden the finish.

Cleanup: Use compressed air to clear residual powder from the gun.

5. How to Choose Manual Powder Coating Spraying Equipment

Budget: Start with basic kits for occasional use; upgrade for frequent projects.

Powder Compatibility: Ensure the gun supports epoxy, polyester, or hybrid powders.

Portability: Opt for lightweight guns and compact ovens for mobility.

Efficiency: Select models with ≥80% transfer efficiency to minimize waste.

Brands like Eastwood and Pro-Tech offer reliable options.

6. Safety Precautions for Manual Powder Coating Spraying Equipment

Wear NIOSH-approved respirators, gloves, and goggles to avoid inhaling powder.

Work in well-ventilated areas to prevent dust accumulation.

Regularly check grounding wires to eliminate electrostatic risks.

Store powders in airtight containers away from moisture and heat.

7. Design Rationale of Manual Powder Coating Spraying Equipment

Manual systems prioritize simplicity, affordability, and ease of use. Ergonomic spray guns reduce hand fatigue, while corrosion-resistant materials ensure longevity. Modular designs allow easy maintenance, and compact ovens save energy for small batches.

8. Q&A on Manual Powder Coating Spraying Equipment

Q1: How long does a manual powder coating gun last?

A: With proper care, guns last 3–5 years. Regular cleaning extends lifespan.

Q2: Can I coat plastic surfaces with this equipment?

A: Yes, if the plastic is heat-resistant and properly pre-treated.

Q3: What is the ideal voltage setting for manual guns?

A: 40–60 kV works for most materials; adjust based on powder type.

Q4: Are manual systems energy-efficient?

A: Yes, compact ovens and low-power guns reduce energy use.

Q5: Is training required for manual equipment?

A: Basic training on grounding and spraying techniques ensures safety and quality.

This guide equips users with essential knowledge about Manual Powder Coating Spraying Equipment, enabling cost-effective, high-quality finishes while prioritizing safety and efficiency.

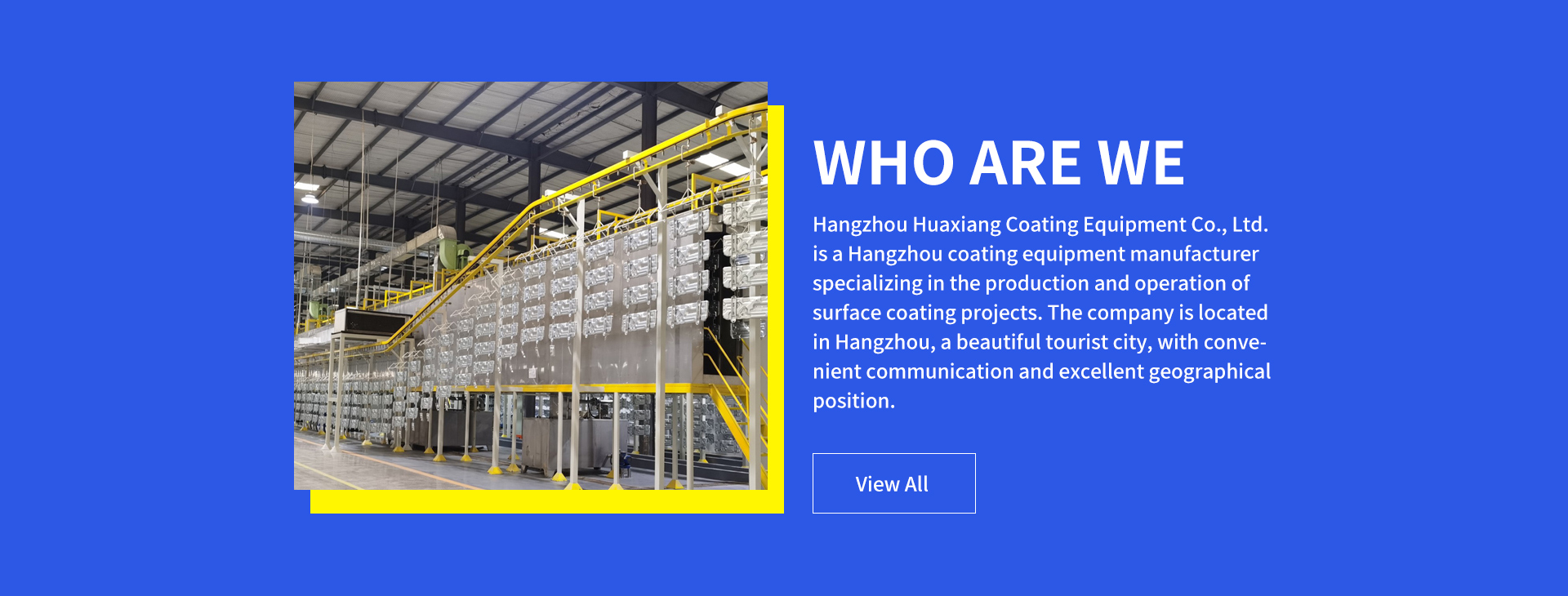

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com